工艺特点:

1.干燥速度快,单位体积蒸发强度较高。

2.成品较细(粉料粒径在50um以下),无易损件

3.适用范围广,能雾化高粘度、高含固水相法或溶剂法工艺产物料;干燥的同时能回收溶剂。

Process features:

1. High drying speed.,Higher unit volume evaporation strength.

2. Fine finished product (size of powdery material is under 50um),Free of quick-wear parts

3. Wide application, it can atomize high viscosity and high solid content materials.

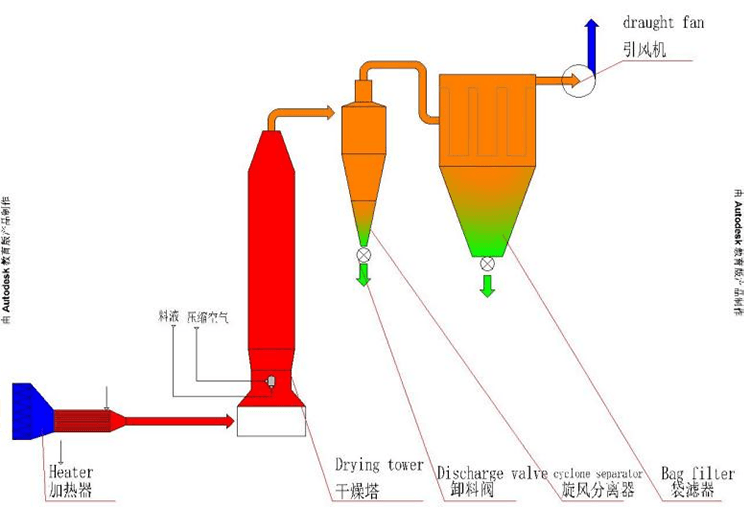

工艺流程简图及工作原理: (敞开型气流喷雾干燥设备工艺)

Scheme of process flow and working principle:

气流式喷雾,又称二流体喷雾,料液由雾化器出料口流出,压缩空气从雾化器的气环口高速喷出(气速达200米/秒以上),当二者在端面接触时,由于二者存在很大相对速度,所产生的高摩擦力及剪切力将料液雾化,并同干燥塔内的热空气进行接触后得到干燥,成品细粉则随气流进入旋风分离器进行气固分离,空气经袋滤器除尘后由引风机引出。

公司研制的三流式雾化器对高粘度、膏状、胶状物均有较好的雾化效果。

Airflow spraying, also called 2 fluid spraying, liquid material is flowed out from outlet of atomizer, and the compressed air is sprayed out in high speed (200m/s) from air ring vent of atomizer, when they touch with each other at the end side, high friction force and shearing force incurred atomize the liquid material as a result of larger relative speed, which is dried after touching with hot air inside the drying tower, finished fine powders enter into cyclone separator along with airflow for gas-solid separation, and the air is output by draught fan after filtering by bag filter.

3 fluid atomizer developed by our company has better atomizing effect for high viscosity, pasty and colloid materials.

(敞开型气流喷雾干燥设备工艺流流程)

(密闭循环式气流喷雾干燥设备工艺简介)

氮气先充盈入密闭式干燥设备系统中,被加热后(非空气)对物料进行烘干作业(原理同敞开式干燥设备系统干燥过程相类似)。烘干后的物料随气流进入旋风除尘器内进行气固分离;尾气进入离线式布袋除尘器内进行过滤除尘;再由引风机鼓入洗涤塔内进行洗涤。洗涤塔内的尾气进入冷凝除湿器内进行冷却、除湿;再被散热器加热重新进行烘干作业。

密闭循环式气流喷雾干燥设备工艺流程

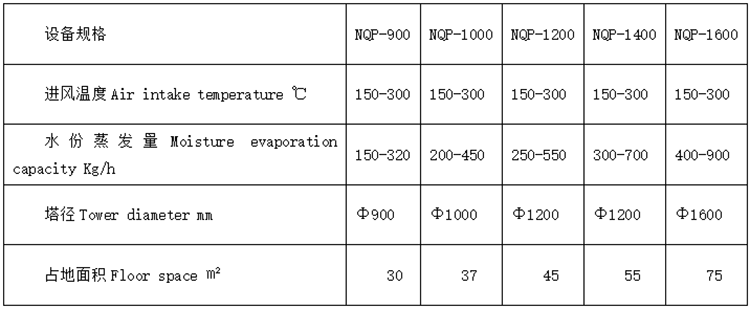

技术性能:(Technical performance:)

适用范围:

Application scope:

该工艺适合于染料、颜料、速溶食品、农药、生化制品、制药、磨料、陶瓷材料、轻工等行业的液状、稀浆状、物料的干燥。

This process is applicable for drying of liquid and serum material in such trades as dyestuff, pigment, instant food,pesticide,biological and chemical products, friction material, ceramic material and light industry etc.

加热方式:

根据厂家具备的条件及物料所能承受温度考虑选择使用蒸气、电或热风炉加热作热源。

Heating method:

steam, electricity or heat air furnace heating can be selected as heat source according to factory conditions and allowed temperature of the material.

典型干燥物料有:

活性染料、分散染料、酸性料、染料助剂、净水剂、增白剂、碳化、氟化钾、二氧化硅、肝血浆、麦芽椒精等。

Typical drying materials:

Active dyestuff, dispersed dyestuff, acid dyestuff, dyestuff assistant, water purifier, whitener, tungsten carbide,potassium fluoride, silicone dioxide, liver plasma and malt etc.

服务热线

服务热线