工艺特点:

1、集粉碎,干燥、分级于一体,连续化生产。

2、适合于粘性物料及非粘性物料的干燥,成品均成粉状。

3、单位产品能耗低,干燥强度大。针对对水相法或溶剂法工艺产物料均可适用;干燥的同时能回收溶剂。

4、干燥时间短(3-15秒),热敏性物料也适用。

Process features:

1.Combining crushing,drying and classification as a whole, realize continuous production.

2. Applied for drying of both sticky and non-sticky materials, finished products are of powders.

3. Lower unit energy consumption and higher drying strength.

4.With short drying time (3-15s), it's also applicable for temperature sensitive materials.

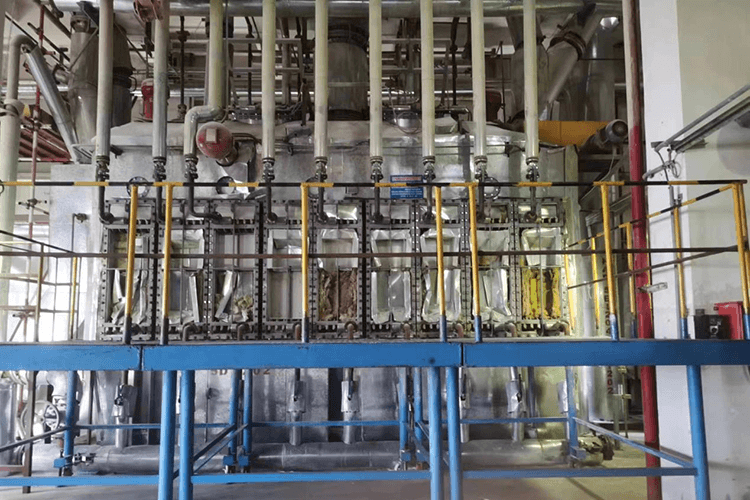

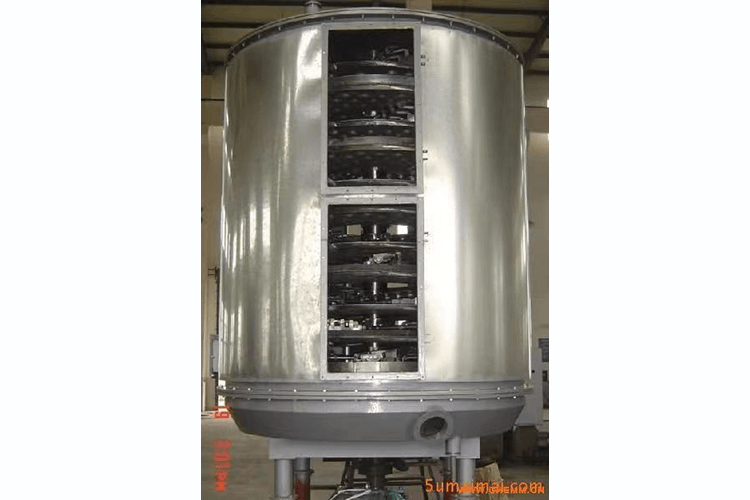

工艺流程简图及工作原理:

滤饼状物料经加料器送入干燥室内,落至干燥室底部,按装在干燥器底部的粉碎装置,将物料进行破碎。干燥用的热空气沿切线方向进入空气分配器,产生的高速旋转气流流经干燥室,将滤饼物料表面先行干燥,粉碎器的机械冲击力和干燥室内热空气的湍动气流对物料产生强烈的剪切、干燥、碰撞、摩擦作用,使得物料快速干燥、微粒化,干燥后的粉料则随气流进入旋风分离器进行气固分离,粉尘由袋滤器回收。

Scheme of process flow and its working principle:

Filter cake material is fed into the drying chamber through feeder and fallen to the bottom of drying chamber, in which, it's crushed by a crusher installed on the bottom of the drier.

Heat air used for drying enters into air distributor with the tangent direction, high speed rotating air flow incurred thereby flows through drying chamber and takes prior drying of surface of filter cake material, mechanical impact force of crusher and swift current of heat air inside the drying chamber produce strong shearing,drying, impact and friction effect to the materials, thus making the material dried and granulated speedily.Dried powdery material enters into cyclone separator for gas-solid separation along with the airflow and dust is recovered by the filter.

(敞开型旋转闪蒸干燥设备工艺流程)

(密闭循型旋转闪蒸环干燥设备工艺简介)

氮气先充盈入密闭式干燥设备系统中,被加热后(非空气)对物料进行烘干作业(原理同敞开型干燥设备系统干燥过程相类似)。烘干后的物料随气流进入旋风除尘器内进行气固分离;尾气进入离线式布袋除尘器内进行过滤除尘;再由引风机鼓入洗涤塔内进行洗涤。洗涤塔内的尾气进入冷凝除湿器内进行冷却、除湿;再被散热器加热重新进行烘干作业。

(密闭循环敞型旋转闪蒸干燥设备工流程)

本产品适用于染料、颜料、涂料、农药、橡胶助剂、矿山等行业的高湿度、高粘度、热敏性的膏糊状、滤饼状、块状、粉状物料的连续干燥,成品均为粉状物。

Application scope:

This process is applicable for continuous drying of high humidity, high viscosity and temperature sensitive pasty,filter cake,lump and powdery materials in such trades as dyestuff, pigment, paint, agricultural chemicals, rubber assistants and mining etc.,finished product is of powder.

.

加热方式:

根据厂家具备的条件及物料所能承受温度考虑选择使用蒸气、电或热风炉加热作热源。

Heating method:

steam, electricity or heat air furnace heating can be selected as heat source according to factory conditions and allowed temperature of the material.

典型干燥物料:

蒽醌、多灵菌、硬脂酸盐、大红粉、水杨酸、碳酸钙、丁酸、柠檬黄、橡胶助剂、叶酸、除草剂、杀虫丹、碳酸锌等。

Typical drying materials:

Anthraquinone,carbendazim, stearate, salicylic acid,calcium carbonate, butyrate, citron yellow, rubber chemicals, folacin,

weedicide, ethiofencarb, zinc carbonate etc.

服务热线

服务热线