工艺特点:

1.它具有高效节能特性,振动能使物料经常性处于流化状态,增大了有效传热系数,跟固定干燥床和气流干燥床相比,可节约能源30-50%。

2.对物料表面损伤少,可用于颗粒物料的干燥,物料颗粒无规则也不影响工作效果。

3.流态化匀称,无死床和吹穿现象。可以获得均匀的干燥、冷却、增湿的制品。

4.可调性好,适应面宽,料层厚度和机内移动速度以及振幅均可实现无级调节。

5.采用振动电机激振并驱动,运转平稳,维修方便,噪音低,寿命长。

6.采用全封闭结构,有效地防止了物料与空气的交叉污染、作业环境清洁,改善了劳动条件。

7.对细粉特殊要求的物料,可增加二级捕集(脉冲)装置,回收率达99.6%以上。针对对水相法或溶剂法工艺产物料均可适用;干燥的同时能回收溶剂。

Process features:

1. Enjoying high efficiency and energy saving, vibration can make the material always in fluidized conditions,thus increasing the effective heat transfer coefficient, which can save energy by 30-50% if comparing with fixed drying bed and air flow drying bed.

2. With little damage to the material surface, it can be used for drying of crushed materials,irregular particulate of material has no influence on working effect.

3. Having uniform fluidization and free of dead bed and penetration, it can get uniformly dried, cooled and humidified products.

4. Good adjustability and wide application, thickness of material layer, internal moving speed and amplitude can be stepless adjusted.

5. Excited and driven by vibrating motor, it features stable running, convenient maintenance, low noise and long service life.

6. Full close structure is adopted to prevent crossing contamination between material and air, realizing clean operation environment and improving the labor conditions.

7. For pulverizing of special material, 2nd phase collecting (pulse) device can be added, recovery rate reaching over 99.6%.

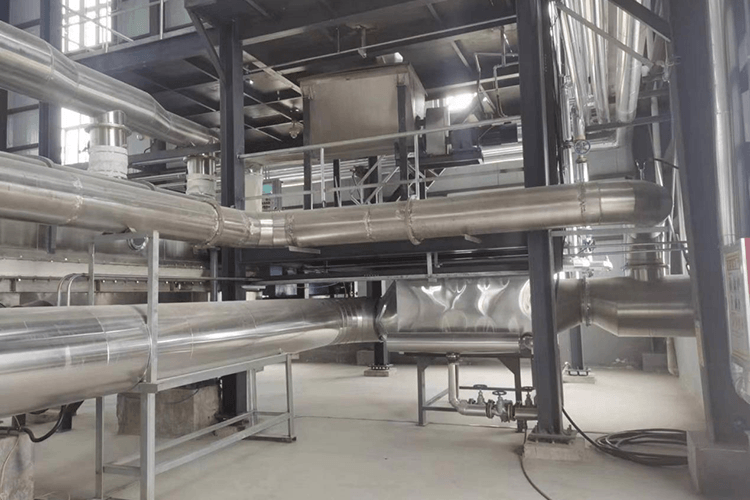

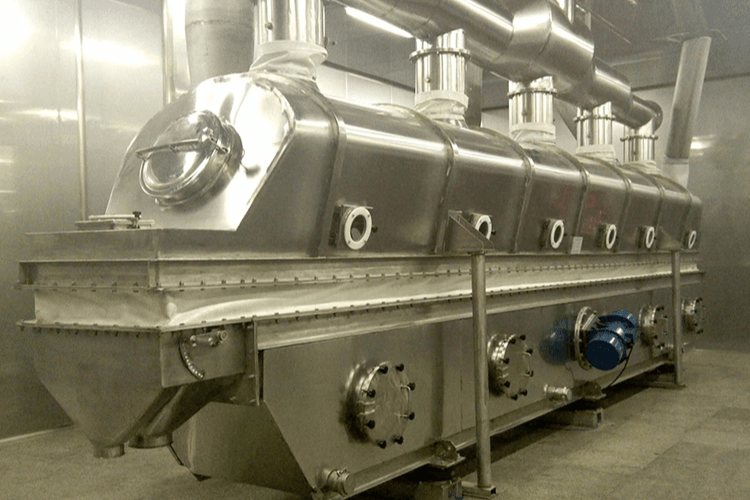

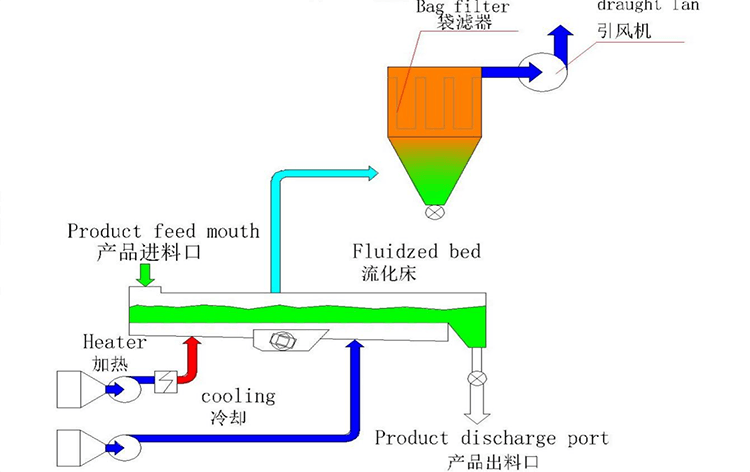

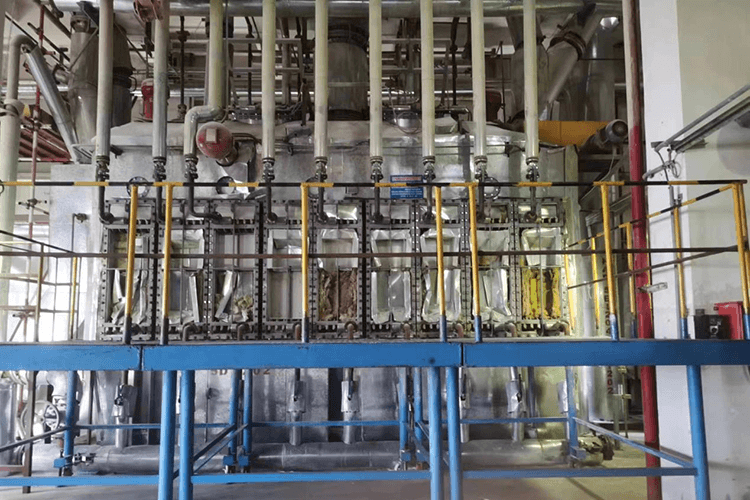

工艺流程及内部结构简图:

Scheme of process flow and working principle:

振动流化床干燥设备是由振动电机产生激振力使床身振动,被干燥物料在这定向激振力的作用下跳跃前进,同时流化床底部输入的热风使物料处于流化状态,物料颗粒与热风充分接触,去掉水份从而达到理想的干燥效果。物料从加料口进入,振槽上的物料与振槽下部通入的热风正交接触传热、传湿,含尘空气由引机引出,干品从出料口排出。

Vibrating motor generates exciting force and makes the bed vibrated, material to be dried is jumped forward under the certain direction exciting force. at the same time, hot air input from bottom of fluidized bed makes the material in fluidized status, at which.material particulates make sufficient touch with hot air, thus removing the moisture content and realizing the purpose of drying. Fed material on the vibrating tank makes cross-out touch with hot air fed from bottom of vibrating tank, thus transferring the heat and moisture, meanwhile, dust air is output from draught fan, dry product is discharged from material outlet.

(敞开型离心式喷雾干燥设备工艺流程)

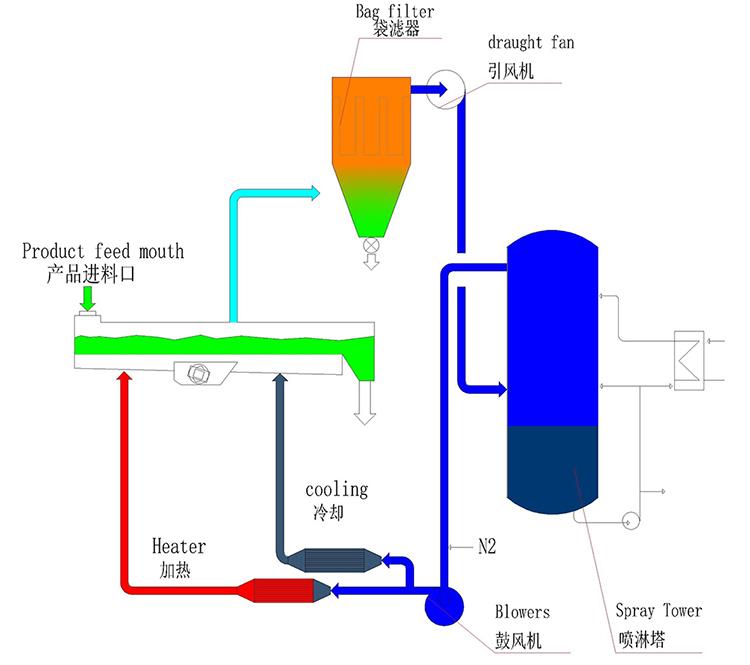

(密闭循环型离心式喷雾干燥设备工艺简介)

氮气先充盈入密闭式干燥设备系统中,被加热后(非空气)对物料进行烘干作业(原理同敞开型离心式干燥设备系统干燥过程相类似)。烘干后的物料随气流进入旋风除尘器内进行气固分离;尾气进入离线式布袋除尘器内进行过滤除尘;再由引风机鼓入洗涤塔内进行洗涤。洗涤塔内的尾气进入冷凝除湿器内进行冷却、除湿;再被散热器加热重新进行烘干作业。

(密闭循环型振动流化床干燥设备工艺流程)

设备参数:

适用范围:

NZG 系列振动流化床干燥机广泛适用于化工、轻工、医药、食品、粮油等行业粉状、颗粒状物料的干燥、冷却、增湿等作业、并表现出明显的优势。

Application scope:

This series of dner is widely used for drying, cooling, moistening of powdery and granula materials in such trades as chemical. light industry, pharmaceutical, food and cereal ete., while showing obvious advantages..

加热方式:

根据厂家具备的条件及物料所能承受温度考虑选择使用蒸气、电或热风炉加热作热源。

Heating method:

steam, electricity or heat air furnace heating can be selected as heat source according to factory conditions and allowed temperature of the material.

典型干躁物料有:

食品饮料行业:

柠檬酸、味精、茶叶、颗料饮料

化工行业:

硼酸、硼砂、草酸、酸、复合肥、硫胺、硝胺、氯化胺、钙镁磷肥、聚氯乙烯、纤维素、活性炭、芒硝、塑料白球

中西药行业:

中药饮片、中药水丸、阿斯匹林、五味子冲剂、感冒胶囊

Typical drying materials:

Lemon acid, monosodium glutamate, tea and granula drinks.

Chemical:

Boric acid, borax, oxalic acid, decanoic acid, zinc permanganate, compound fertilizer,thiamine, nitramine, ammonium chloride,calcium magnesium phosphate, polyvinyl chloride, cellulose,active carbon,reussin,

Traditional Chinese and western medicine:

Medicine material crude slices, water-bindered pill of Chinese medicine, aspirin, electuary of schisandra chinensis,quick result cold capsule

服务热线

服务热线