工艺特点:

1、设备紧凑,体积小,生产能力大。

2、单位产品能耗低,干燥强度大。针对对水相法或溶剂法工艺产物料均可适用;干燥的同时能回收溶剂。

3、干燥时间短(3-30秒),热敏性物料出适用。

Process characteristics:

1. The equipment is characterized by its compact frame, small size and large capacity.

2.Low energy consumption per unit of product, powerful drying capactiy.

3. Short drying time (3-30 seconds), also applicable for heat-sensitive materials.

工作原理:

从加料器加入的物料进入管径小的干燥管内,颗料得到加速,当其加速运动终了时,干燥管径突然扩大,颗粒依惯性进入管径大的干燥管,颗粒在运动过程中,由于受到阻力而不断减速,直到减速终止,干燥管突然缩小,这样颗粒又被加速。如此重复交替的加速和减速,强化了传热、传质速率,使物料在瞬间得到有效的干燥,成品随气流进入旋风分离器作气固分离,粉尘由布袋除尘器回收。

针对成品物料降水要求较高的物料:(中成品水:0.5-0.01%)可串联旋风干燥器对未干成品作二次干燥处理。

在旋风干燥器内气流夹带物料从切线方向进入,沿着内壁形成螺旋线运动,物料在气流中均匀分布与旋转扰动,增大了气固间的传热面积,延长了干燥时间,强化了干燥过程。

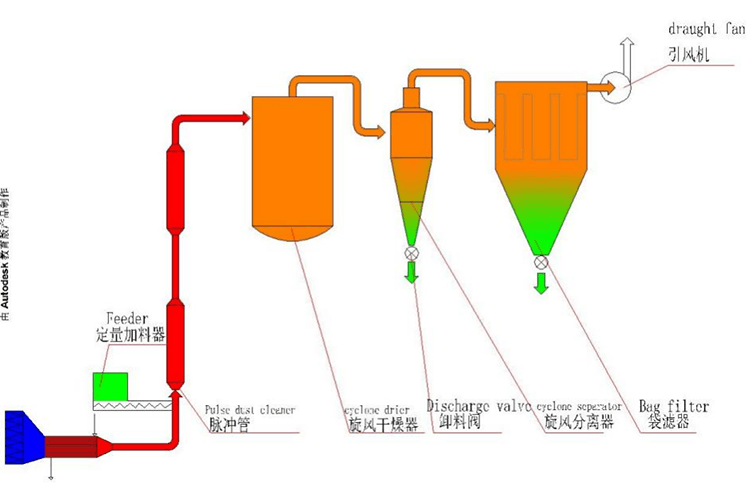

Working Mechanism:

The materials are fed into a drying-tube with diameter, and accelerated by the hot hair at a high speed. Suddently, the materials rush into a thicker part of drying-tube by inertia. In movement, the speed of material particles is gradually decelerated until the speed is constant. Then the drying-tube diameter becomes much smaller again so that the particles are accelerated again.Through repeated alternation of acceleration and deceleration, a high efficiency of heat-transferring and mass-transferring is obtained so that the materials are dried instantly. At last, the dried product goes with the air-flow into the cyclone sparator for gas-solid separation, and dust is collected effectively by the bag filter.

As to the materials of high drying requirement(Dried product containing water: 0.5~0.01%), pulsed air dryer is applied to drying for the second time.

Air-flow with materials goes into the cyclone dryer in the tangential direction, then moves in a spiral along the inner wall of the dryer. The materials are evenly distributed in the air-flow with swivel disturbance so that heat-transferring area is enlarged, drying time is lengthened and drying process is enhanced.

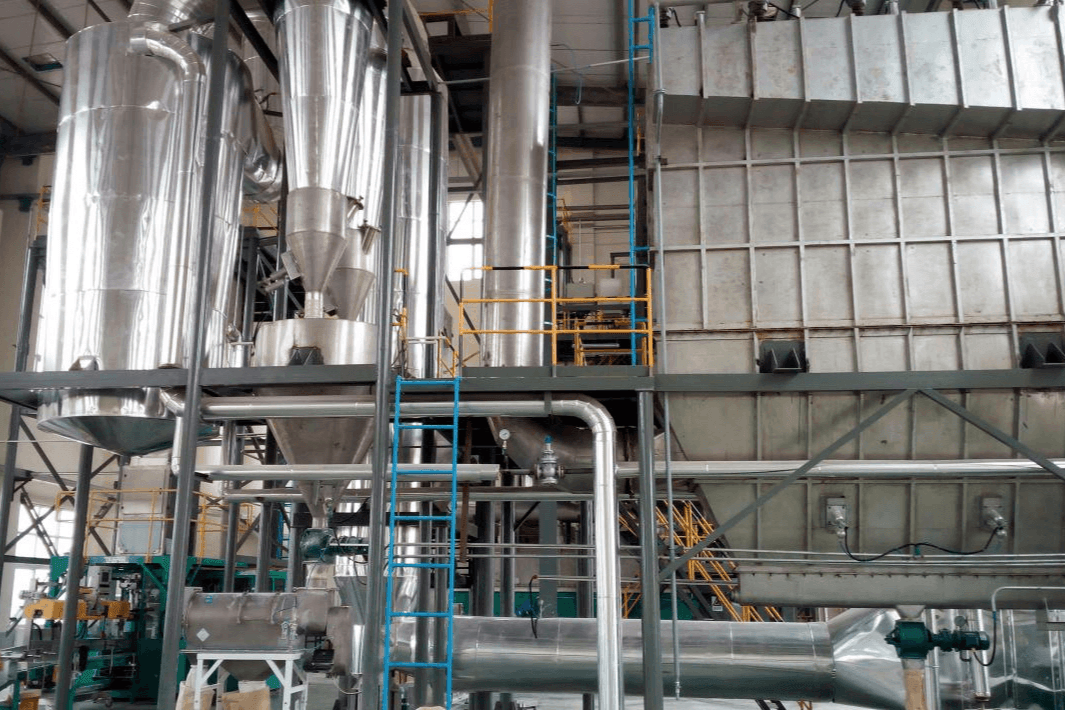

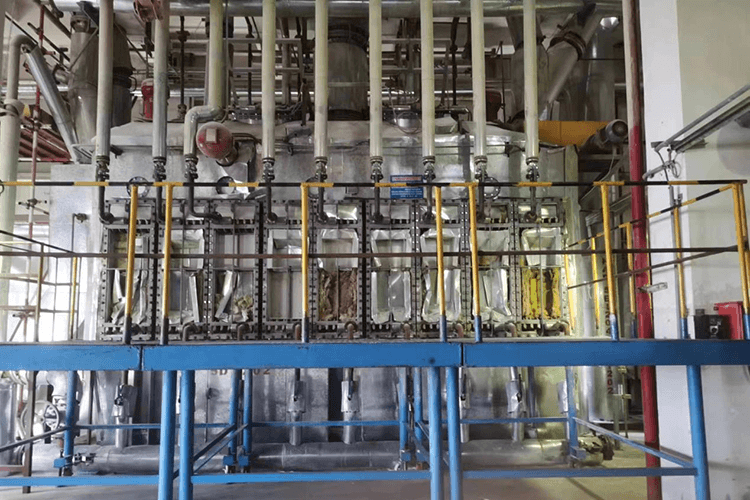

工艺流程及内部结构图:

(敞开型气流脉冲干燥设备工艺流程)

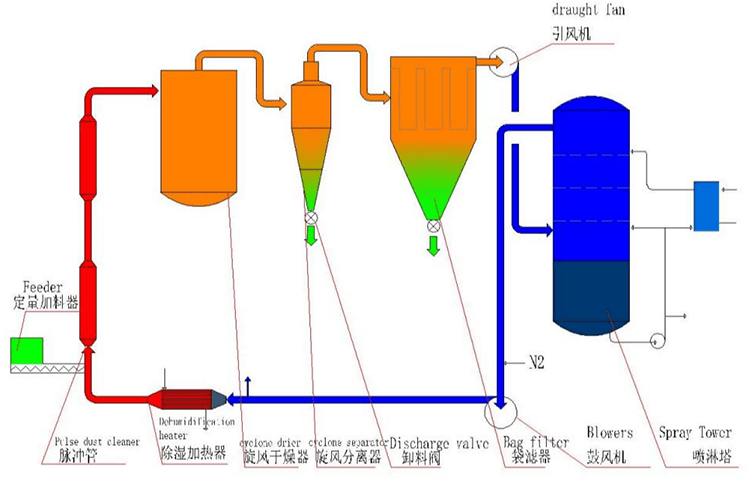

(密闭循环型气流脉冲干燥设备工艺简介)

氮气先充盈入密闭式干燥设备系统中,被加热后(非空气)对物料进行烘干作业(原理同敞开型干燥设备系统干燥过程相类似)。烘干后的物料随气流进入旋风除尘器内进行气固分离;尾气进入离线式布袋除尘器内进行过滤除尘;再由引风机鼓入洗涤塔内进行洗涤。洗涤塔内的尾气进入冷凝除湿器内进行冷却、除湿;再被散热器加热重新进行烘干作业。

(密闭循环型气流脉冲干燥设备工艺流程)

技术性能:(Technical performance)

适用范围:

该工艺设备适合于矿业、化工、轻工等行业的颗粒状、粉状物料的干燥,成品为粉状。

Application scope:

This type of equipment is made for mining, chemical industry, light industries for drying both particles and powder materials.Finished product is powder.

加热方式:

根据厂家具备的条件及物料所能承受的温度考虑选择使用蒸气,电或热风炉加热作热源。

Heating method:

steam, electricity or heat air furnace heating can be selected as heat source according to factory conditions and allowed temperature of the material.

典型干燥物料有:

硼砂、磺胺、季戊四醇、草酸、玉米淀粉、保险粉、亚硫酸钠、苯甲酸、活性炭、树脂、硬脂酸盐、糠氯酸等。

Typical drying materials are:

Borax,sulfonamides, pentaerythritol, oxalic acid, corn starch, sodium hydrosulfte, sodium sulfte, sodium benzoate, benzoic acid,activated carbon, resin, stearic acid salt, sugar, and other chlorine net.

服务热线

服务热线