工艺特点:

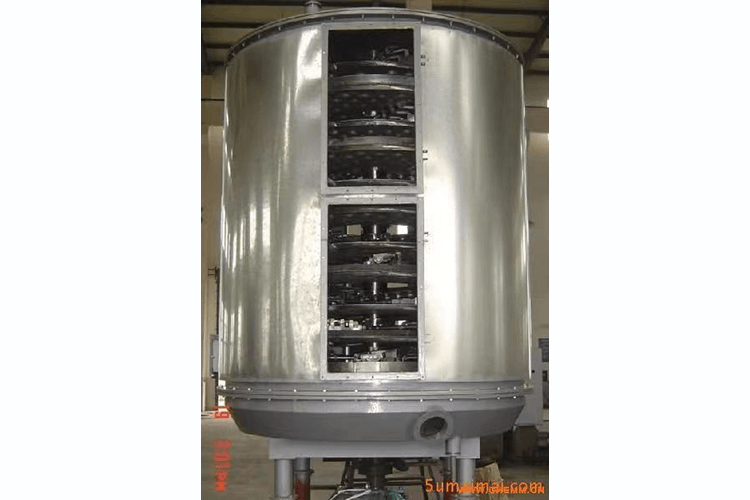

(一).操控容易、适用性广。

1、通过调整料层厚度、主轴转速、耙臂数量、耙叶型式可优化干燥处理效果。

2、每层干燥盘皆单独通入热媒或冷媒,可对物料进行加热或冷却处理。

(二).操作简单,一键式起动。且干燥机内转动的耙叶对干燥盘内的物料有自动刮落、清理功能。同机内更换干燥物料,交叉污染较少。

(三).能耗低。传导式加热、密闭式作业,空气流出量很少,热量及动力损耗大为降低。

(四).操作环境友好,粉尘排放符合环保要求。配备冷凝回收装置,真空密闭型干燥设备可回收有机溶剂。

(五).安装方便。主机可一次性吊装到位,整机占地面积小。

Process features:

1. Easy to operate and widely applicable.

1.1 The drying effect can be optimized by adjusting the thickness of the material layer, spindle speed, number of rake arms, and rake blade type.

1.2 Each layer of drying tray is separately fed with heating or cooling media, which can heat or cool the materials.

2. One-button start. The rotating rake blades inside the dryer have automatic scraping and cleaning functions for the materials in the drying tray. Replacing dry materials within the same machine reduces cross contamination

3. Low energy consumption. Conductive heating and enclosed operations result in minimal air flow, greatly reducing heat and power losses.

4. Environmentally friendly, dust emissions meet environmental requirements. Equipped with a condensation recovery device, vacuum enclosed-type dryer can recover organic solvents.

5. Easy to install. The host can be lifted into place at once, and the entire equipment occupies a small area.

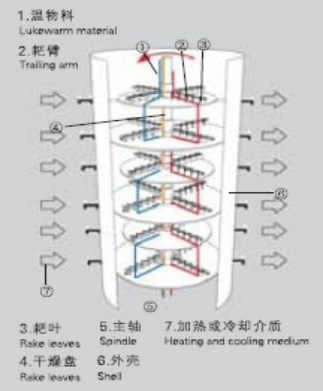

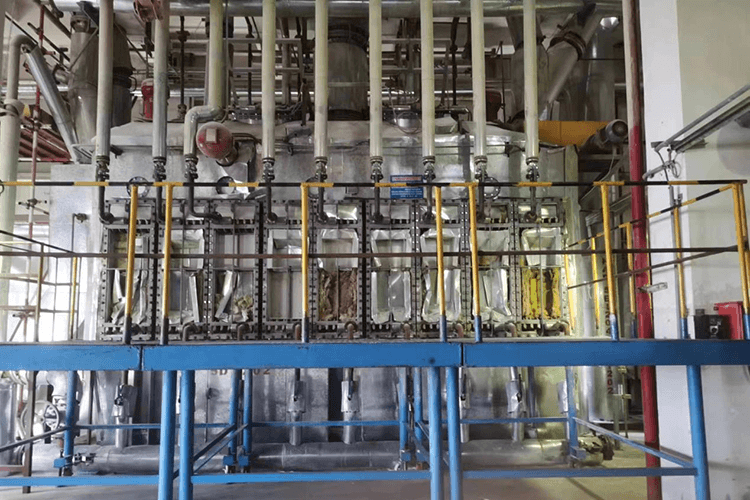

工艺流程简图及工作原理:

湿物料自加料器连续地加到干燥器上部第一层干燥盘上,带有耙叶的耙臂作回转运动,使耙叶连续地翻抄、移位物料;不断的更换受热表面。物料沿指数螺旋线流过干燥盘表面,在小干燥盘上的物料被移送到外缘,并在外缘落到下方的大干燥盘外缘,在大干盘上物料向里移动并从中间落料口落如下一层小干燥盘中。大小干燥盘上下交替排列,物料得以连续地滑过整个干燥器。中空的干燥盘内通入加热介质,加热介质形式有饱和蒸汽、热水或导热油等热介质,加热介质由干燥盘的一端进入,从另一端导出。已干物料从最后一层干燥盘落到壳体的底层,最后被耙叶移送到出料口排出。湿份从物料中析出,由设在顶盖上的排湿口排出(真空型盘式干燥器的湿气由设在顶盖上的真空泵口排出)。干物料从底层排出直接包装。

通过配加翅片加热器、溶剂回收冷凝器、袋式除尘器、干料返混机构、引风机等辅机,可提高其干燥的生产能力,干燥膏糊状和热敏性物料,可方便地回收溶剂,并能进行热解和反应操作。

Scheme of process flow and its working principle

Wet materials are continuously added from the feeder to the first layer of drying plate on the upper part of the dryer, and the rake arm with rake blades rotates to continuously flip and shift the materials; Continuously replace the heated surface. The material flows through the surface of the drying tray along an exponential spiral. The material on the small drying tray is transferred to the outer edge and falls to the outer edge of the large drying tray below. On the large drying tray, the material moves inward and falls into the next layer of small drying tray from the middle discharge port. The size of the drying tray is arranged alternately up and down, allowing the material to continuously slide through the entire dryer. The hollow drying plate is filled with heating medium, which can take the form of saturated steam, hot water, or thermal oil. The heating medium enters from one end of the drying plate and exits from the other end. The dried material falls from the last layer of the drying plate to the bottom layer of the shell, and is finally transported by the rake blades to the discharge port for discharge. Moisture is precipitated from the material and discharged through the dehumidification port located on the top cover (the moisture in the vacuum disc dryer is discharged through the vacuum pump port located on the top cover). Dry materials are discharged from the bottom layer and directly packaged.

By adding auxiliary machines such as finned heaters, solvent recovery condensers, bag filters, dry material mixing mechanisms, and induced draft fans, the drying production capacity can be improved. Drying paste like and heat sensitive materials can easily recover solvents and perform pyrolysis and reaction operations.

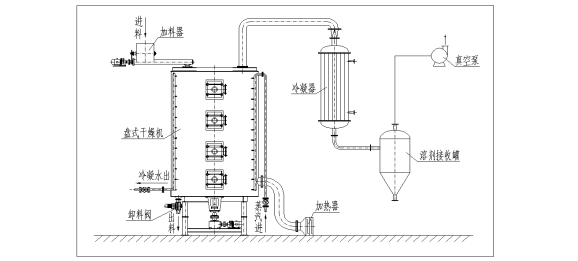

真空密闭型盘式连续干燥设备流程:

Process flow of vacuum enclosed-type disc continuous dryer

负压型盘式连续干燥设备流程:

Negative-pressure type disc continuous dryer

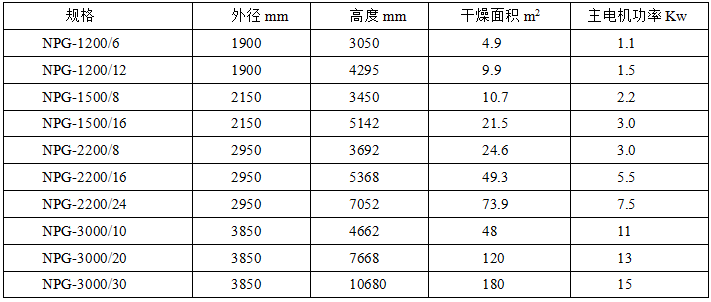

技术性能: Technical performance

适用范围:

本产品适用于化工、染料、农药、塑料、医药、食品等众多行业中的热敏性颗粒状、粉末状物料。

Application scope:

NPG series disc continuous dryer is applicable for thermosensitive granular and powdered materials in many industries such as chemical, dye, pesticide, plastic, pharmaceutical, and food.

除尘器的配置:

根据物料的特点,可选用布袋除尘器、湿喷淋除尘器作二级除尘设备,也可通过冷凝器回收溶剂。

Configuration of dust collector:

According to features of material, bag dust collector, wet dust collector or wet spraying dust collector can be used as 2nd phase dust removal equipment.

加热方式:

根据厂家具备的条件及物料所能承受的条件考虑选择使用蒸汽、热水或导热油加热做热源。

Heating method:

Consider using steam, electricity, or hot air stoves as heat sources based on the conditions provided by the manufacturer and the temperature that the materials can withstand.

典型干燥物料有:

有机化工产品(聚氯乙烯树脂、聚四氟乙烯树脂、苯胺、甲酸钙、三乙烯二胺、酸性黑染料等)

无机化工产品(轻质碳酸钙、活性碳酸钙、碳酸镁、氢氧化铝、碳酸钾、氯化钠等)

医药、食品(维生素C、盐、氢氧化铝、氨苄青霉素、淀粉、巧克力粉等)

饲料、肥料(生物钾肥、蛋白饲料、菌丝体、酒糟、粮食、种子、纤维素、除草剂等)

Typical drying materials:

Organic chemical products; polyvinyl chloride resin, polytetrafluoroethylene resin, aniline, calcium formate, triethylenediamine, acidic black dye, etc.

Inorganic chemical products: light calcium carbonate, active calcium carbonate, magnesium carbonate, aluminum hydroxide, potassium carbonate, potassium hydroxide, sodium chloride, etc.

Medicine and food:vitamin C, medicinal salts, medicinal aluminum hydroxide, ampicillin, starch, chocolate powder, etc.

Feed and fertilizer: bio potassium fertilizer, protein feed, mycelium, distiller's grains, grains, seeds, cellulose, herbicides, etc.

服务热线

服务热线